#multi-axis load cell

Explore tagged Tumblr posts

Text

Forsentek Co., Limited supplys multi axis load cells for force measurement and control in industrial field. 3 axis load cell

#3 axis load cell#multi axis force sensor#multi-axis load cell#3-axis force sensor#triaxial load cell

1 note

·

View note

Text

Website: http://www.loadcellsensor.com/

Address: Rm 1605, Ho King Commercial Center, 2-16 Fa Yuen St., Mongkok, Kowloon 999077, Hong Kong China

Phone: +86-19956502838

LCS Tech Co., Ltd is a Chinese manufacturer for strain gauge type load cell sensors,tension compression force transducers, reaction and rotary torque sensors.

#load cell sensor#tension compression load cell#multi-axis force sensor#rotary torque sensor#reaction torque transducer

1 note

·

View note

Text

Forsentek Co., Limited Elevates Measurement Precision with Newest Small Load Cell, Force Transducer, and Multi-axis Load Cell

http://dlvr.it/T7ym5S

0 notes

Text

Forsentek Co., Limited Elevates Measurement Precision with Newest Small Load Cell, Force Transducer, and Multi-axis Load Cell

http://dlvr.it/T7yYdm

0 notes

Text

Forsentek Co., Limited Elevates Measurement Precision with Newest Small Load Cell, Force Transducer, and Multi-axis Load Cell

http://dlvr.it/T7yPVj

0 notes

Text

The Latest Trends In Machine Shop Equipment Auctions

Machine shop equipment auctions reflect the evolving needs and technological advancements within the manufacturing industry. Keeping abreast of the latest trends can help bidders identify valuable opportunities and stay competitive in acquiring cutting-edge equipment.

Here are some of the latest trends in machine shop equipment auctions:

CNC Machines Dominate: Computer Numerical Control (CNC) machines continue to dominate machine shop equipment auctions. These automated machining tools offer precision, efficiency, and versatility in manufacturing processes. Bidders can expect to find a wide range of CNC equipment, including CNC mills, lathes, routers, and plasma cutters. As CNC technology advances, newer models with enhanced features such as multi-axis machining, faster spindle speeds, and integrated automation systems become available at auctions.

Industry 4.0 Integration: Machine shop equipment is increasingly incorporating Industry 4.0 technologies for enhanced connectivity, automation, and data-driven decision-making. Bidders can find equipment with features such as IoT sensors, predictive maintenance capabilities, and cloud-based monitoring systems. These advancements enable real-time monitoring of machine performance, proactive maintenance scheduling, and remote diagnostics. Equipment with Industry 4.0 integration offers improved efficiency, reduced downtime, and better overall productivity, making them highly sought after in auctions.

Additive Manufacturing: Additive manufacturing, including 3D printing and rapid prototyping technologies, is gaining traction in machine shop equipment auctions. Bidders can find a variety of additive manufacturing machines capable of producing complex geometries and customized components. From industrial-grade 3D printers to selective laser sintering (SLS) machines, these technologies offer innovative solutions for rapid production, prototyping, and tooling applications.

Hybrid Machining Systems: Hybrid machining systems, combining additive and subtractive manufacturing processes, are emerging as a trend in machine shop equipment auctions. These systems integrate traditional machining methods with 3D printing or laser deposition technology, allowing for the creation of complex parts with improved accuracy and surface finish. Bidders can explore hybrid machines that offer the flexibility to switch between additive and subtractive processes based on the application requirements.

Robotics and Automation: Robotics and automation are revolutionizing machine shop operations, and their presence is evident in equipment auctions. Bidders can find robotic arms, automated material handling systems, and robotic machining cells designed to streamline production processes and improve efficiency. These robotic systems offer capabilities such as part loading/unloading, tool changing, and in-process quality inspection. By integrating robotics and automation, machine shops can achieve higher throughput, lower labor costs, and greater consistency in production.

Environmental Sustainability: Environmental sustainability is becoming a key consideration in machine shop equipment auctions. Bidders are increasingly seeking equipment that incorporates energy-efficient features, waste reduction measures, and eco-friendly materials. Machines with features such as regenerative braking, energy-saving modes, and coolant recycling systems are in demand. Additionally, equipment designed for minimal environmental impact, such as water-based cutting systems and low-emission machining processes, are gaining popularity among environmentally-conscious bidders.

Remote Access and Monitoring: Remote access and monitoring capabilities are essential features in modern machine shop equipment auctions. Bidders look for equipment that allows for remote operation, diagnostics, and performance monitoring via computer or mobile devices. With remote access, operators can manage machines from anywhere, optimize production schedules, and troubleshoot issues without being physically present on the shop floor. Equipment with remote monitoring capabilities offers greater flexibility and efficiency in today's interconnected manufacturing environments.

In summary, machine shop equipment auctions reflect the latest trends in manufacturing, including the widespread adoption of CNC technology, Industry 4.0 integration, additive manufacturing, and robotics. Bidders can capitalize on these trends by acquiring equipment that offers advanced capabilities, improved efficiency, and enhanced productivity for their machining operations.

0 notes

Text

Excessive Automatic Palletizer Machine Stage

This course of repeats till a full layer of products and products are configured to be placed on a pallet. The system is designed to ensure full performance even in heavy seas. The outcome is a robust computerized palletizer machine of excessive quality that saves an unlimited quantity of area. Columbia's conventional high level palletizer machines set the industry normal automatic palletizer machine.

Because your specifications for palletizing are reliably met, hundreds are much less likely to incur damage during loading, cargo and unloading. Roll feed, Hot soften, Cold glue, Self-adhesive and shrink sleeve labelling machines in standalone or mixed variations for various formed bottles. Linear and Rotary Rinsing, Filling & Capping solutions utilizing Net weight, Flow meter and Level filling technologies. A low friction curler transfer desk is out there to allow easy handling of heavy and shrinkwrapped circumstances.

Feed and orient empty plastic containers of various shapes & sizes to the filling line mechanically. Achieve maximum output with minimal downtime for peak effectivity and machine profitability. Our palletizing consultants help with each step of the method and stand by 24/7 to resolve any questions.

No lifting, stooping or strolling around the pallet is required to operate this case palletizer.

An automatic palletizer can present up to 60 baggage per minute, nonetheless, it's nonetheless potential to extend this fee by integrating a second robotic to the cell which optimizes velocity.

Wearproof steel guides make positive the curler bearings roll efficiently.

In some palletizing stations, when a pallet layer is full, the operator lowers the work surface as required to hold up a comfortable working height.

The Science of Palletizing is a 72-page educational introduction to the basics of unit-load forming and is designed to familiarize you with the basics of automatic palletizer machine.

The use of 6-axis robots allows most flexibility in palletizing schemes, structure and built-in extra functions. Compact and strong design combined with a laterally mounted vertical linear axis system result in a low general machine peak which permits the use even with low ceiling heights. Multi-axis automation products together with H-Bots, T-Bots, Gantries, and Cartesian Robots. Our palletizer is a perfect alternative for palletizing aboard factory trawlers, because the stretch movie is added while the machine palletizes.

Of course, product is transferring all the time and often has to go very far before reaching its destination. But getting it there is only half the battle; the other half is getting it to the ultimate automated palletizer consumer in an interesting, salable condition. This design permits three pallets to be stacked on the ground on each side.

Trust in our four-station palletizer with supreme operating consolation. The pallet magazine is built-in with a switch system that enables for a completely computerized pallet dealing with process. Automatic conveying and palletizing system is used for palletizing unit load, together with various carton bins in paper-making, food and medicine business and so forth. Depending on package deal weight and load configuration, manual palletizing may be backbreaking work. [newline]Automating these processes can scale back publicity to continual injuries and potentially severe accidents. An automatic palletizer can decrease worker’s compensation prices and enhance employee satisfaction on the same time.

Excessive Stage Palletizers

In some cases, pallets are moved away from the machine and packed/wrapped both by hand or by another machine. Columbia Machine offers the most innovative and flexible palletizing options available. Columbia standard palletizers deal with nearly any bundle sort together with trays , shrink-only bundles, RPCs, Totes, tab-lock instances, milk crates and a lot extra.

In the top, robotic computerized palletizers supply extra flexible and dependable options than standard methods. These solutions make it attainable to evolve with the rising needs of an organization. Low upkeep costs and easy palletizing sample changing add to the advantages of a faster return on financial investment. Their excessive reliability and low maintenance demand give them a transparent advantage over standard methods. Nowadays working with palletizing equipment is of a crucial significance in numerous industries worldwide. Therefore, palletizing machines are generally utilized in wooden and paper industry, metal industry, construction trade as properly as in beverage and meals business.

Commonality of part techniques allow cost financial savings for end customers, rapid supply and proven performance with future flexibility when required. Equipped with a forty one" Wide x 48" Long x fifty three" High pallet stacking part, seventy two" long chain infeed conveyor extending 12" past body with a 34" infeed top. Equipped with a forty one" Wide x forty" Long x forty eight" High pallet stacking section, one hundred twenty" lengthy chain infeed conveyor extending seventy eight" past body with a 37" infeed top.

The use of a collaborating robotic permits an open layout with out safety fences. This ensures greatest accessibility and minimizes the house requirement on your shopfloor. Proven drive technology with frequency controlled AC motors guarantee excessive reliability and are easy to keep up. Compact and robust portal building allows a small foot print and good accessibility.

In order to acquire a complete solution, additional options could be built-in to the top of the production line getting ready your pallet for storing or transport. Conveyorized palletizers have a feed area that receives the products which are to be palletized. The packaged items are obtained by curler conveyors and are continuously transferred and sorted to the pallets by automated conveyor rollers, permitting higher packaging speed than robotic palletizers. Robotic systems also can offer several advantages over conventional machines.

There are 5,447 palletizer machine suppliers, mainly situated in Asia. The top supplying country or region is China, which provide 100 percent of palletizer machine respectively. Easy to make use of, with superior options including easy pattern edit/creation. Our palletizers contribute to an efficient processing course of and preserve the standard of your powders. You have selections in relation to packaging supplies and on this webinar, we'll walk via totally different materials and the way it impacts your provide chain.

Innovative automated gripper that ensures precise positioning on the pallet. Safe and stable transport is a prerequisite to ensure that your product reaches its destination whereas safeguarding the standard. TopTier Sales Engineers provide price range quotes in a matter of days. Cost is based on particular products to be handled, fee requirements, layout, and desired features. Format vary subject to feeding and collating system and features of machine.

Robotic palletizing arrived later and introduced with it many advantages in comparability with standard techniques. Reliability and flexibility are some of the property these techniques have to offer. Additionally, if you need upkeep and repair, Robopac USA offers full help through our components and service division. We also can advise you on potential upgrades to improve your machine’s effectivity and presumably lengthen its life. View our TopTier palletizer machines for sale to find out the finest option on your facility.

For these larger footprints and attain conditions a user can simply add a further axis to meet any problem. To obtain the improvements automation techniques produce, it is essential to select one of the best combination of robot fashion, gripper and auxiliary equipment to match the production need. An automation options integrator can provide the proper answer for any palletizing software. Conventional palletizers usually use a layer approach that forms the pack pattern of instances, squeezes them into form and deposits them one layer at a time onto the pallet. This palletizer may be broken down into two categories – a low-level or high-level palletizer.

Dairy Products

Accessible and highly sensible respecting operator security with the photoelectric obstacles. The robotic or choose and place is customised to delicately deal with the product and turn it to the appropriate place before placing it into the pallet. Simple configuration called “GROUND PALLET” the place the empty pallet is positioned by an operator with the pallet truck by hand. Picking the stuffed pallet takes place in the identical means with the pallet truck by hand by an operator.

Fully Automatic 25kg Kraft Paper Valve Bag Filling Production Packing Line Palletizer

Brenton engineers and manufactures case packing, palletizing and built-in packaging systems. Robotic automatic palletizers are designed to adapt to present traces and area to have the ability to enhance production rates or adapt to new merchandise. An automated palletizer can present as much as 60 bags per minute, however, it is nonetheless possible to extend this fee by integrating a second robot to the cell which optimizes speed. Safety systems are the most advanced within the trade, with the highest attainable security score.

Semi-automatic palletizing tools, which is well-liked in area of interest markets the place merchandise are heavy and troublesome to palletize manually, can deal with as much as 20 bags or instances per minute. This tools is nicely suited to low-speed operations that can’t justify the worth of full automation however require a solution to help forestall worker damage. Aagard is an engineering company that builds custom packaging automation techniques. Our group of inventive problem-solvers utilizes our progressive expertise and proven technologies to create the exact solution that our prospects must win.

Fully automated mannequin consists of pallet handling, stretch wrapping, load exit conveyor, and security access doorways. Fully automated model includes pallet dealing with, stretch wrapping, load exit conveyor, mezzanine, and security entry doors. They are excellent for medium to excessive pace vegetation and multiline functions. Hamer absolutely automating palletizing techniques utilize automatic in-feed conveyors to tempo product in-feed to the pick-and-place palletizing station. The product is then stacked on empty pallets with or with out slip sheets, that are automatically fed to the stacking space. Once a pallet has been accomplished it is prepared for forktruck pickup or it is transferred to the in-line stretch wrapping/hooding equipment to mechanically complete the pallet for cargo.

Palletizers are mostly integrated in a much bigger packaging system line, which ensures quick and environment friendly packaging for a spread of products. A hydraulic robotic arm lifts circumstances, bottles, bags or drums using flat pincer arms or suction cup arms in organized rows onto a pallet, stacking items with near-perfect precision. Massman Automation integrates ABB, Fanuc, or Motoman robots into the robotic palletizing cell. These techniques deal with a quantity of packaging strains with a number of SKUs that includes ALBA pallet dispensers and pallet conveyors that are appropriate with many custom-designed case and pallet dealing with methods. PalKombi is an computerized palletizer suitable for crates, cartons, trays, shrink-wrapped packs and all kinds of packages in general. Designed for medium to high speeds, PalKombi works with a gentle low-level infeed pallet.

This compact structure provides minimum house usage and works well in slim spaces. If your workers are engaged on different strains on different days, they'll take the palletizer to their workplace. Movable on rollers and with pallet guides folded up, PalTeq Cobot suits via doorways from 900 mm width.

Manually putting bins on pallets may be time consuming and costly; it could additionally put unusual stress on employees. PalTeq Robot is our fully automatic robot palletizer for palletizing of shipping instances or trays, or almost all type of stackable products. Due to our modular building platform the layout can be designed almost freely and extra features can be built-in easily. Macron Dynamics presents a Cartesian fashion MGS-UC2 linear robot kit that can be built-in into palletizing systems. The Macron MGS-UC2 gantry product is a sturdy and sturdy 2-axis system with broad payload capacity. This ready-made kit, in pre-configured commonplace travel lengths, contains integrated cable management, low profile T-slot sensors and MPG gearboxes ready for any motor mounting.

The VPG palletizer is designed with a particular gripping head, so to stack the bags in an overlapping manner. This palletizer version has a special rotating head, so the product may be imported at excessive pace. We are a professional manufacturer & exporter specialized in numerous tin cans making machinery. [newline]We are always able to develop long-term and good relationship with abroad customers. If you want to know more about us, please don’t hesitate to contact us at any time. SPLX MKII High Level Palletizer’s key parts are primarily maintenance-free, and are simply accessible via detachable guards and doorways.

Manual palletizing may be carried out by people and without any mechanical help at all. Furthermore PalTeq Cobot offers tool-less kind change and changeover between totally different pallet sorts. By using totally different robot sizes we are in a position to all the time offer you the ideal space-optimized structure for every product weight. Proven technology with frequency managed AC drives guarantees high reliability and straightforward maintenance. Using a novel, flexible belt based mostly “rack and pinion” design and structural aluminum MacFRAME parts, our Robotic Transport Units can handle all kinds of lengths and payloads.

1 note

·

View note

Text

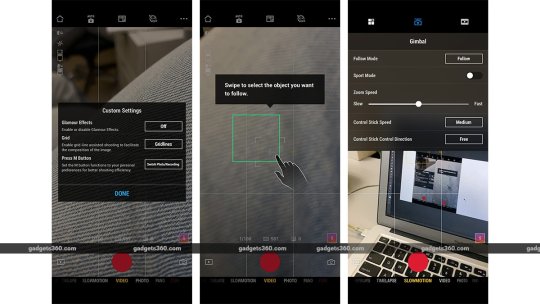

DJI Osmo Mobile 3 review

DJI is popularly known as a manufacturer of drones and handheld stabilizers for cameras. Even though it recently entered the field of action cameras with the Osmo Action, its strengths remain in the production of high-quality gimbals for smartphones and cameras. The most recent launch was Osmo Mobile 3, the handheld stabilizer for 3rd generation smartphones. This 3-axis gimbal is a great tool for content creation, especially if your phone doesn't have the best electronic or optical stabilization. The Osmo Mobile 3 gets some nice improvements over its predecessor. It is now foldable to improve mobility. has better ergonomics; and has new shortcuts and gestures. We've been using the DJI Osmo Mobile 3 for about a week now, and here's what we think of it.

DJI Osmo Mobile 3 design and features

The Osmo Mobile 3 is available in India as a standalone device for Rs. 8,999 or as a "combo" for Rs. 10,999, which includes a hard carrying case and an Osmo Grip tripod. The latter does not add extra height to the gimbal, but has foldable feet so that when closed, it can be used as an extended handle or as a normal tripod. The Osmo Mobile 3 weighs only 405 g and is therefore quite light. The handle and most parts of the gimbal itself are made of plastic, but the quality is very good. The handle is covered with plenty of rubber to additionally support the sweaty palms. The arm of the gimbal can now be folded to make it easier to carry. You can even attach a phone to it when folded, which is convenient. With the 3-axis stabilization, you can perform tilting, rolling and swiveling movements while recording. The main buttons are located on the front of the handle. This includes a multi-directional joystick and buttons for recording and switching between the recording modes (& # 39; M & # 39;). There is a zoom control on the left and a USB Type-C port for charging on the right.

The DJI Osmo Mobile 3 has ergonomically placed buttons on the handle The Osmo Mobile 3 also has a full-size USB Type-A port on the handle in case you need to charge your phone while recording. Finally, we have an ergonomically placed release button on the back of the handle that can be used to reset the position of the phone. Depending on the number of clicks, the sport mode can also be activated and the tilt axis locked, and you can switch between the rear and front cameras of your phone. The Osmo Mobile 3 has a standard tripod mount on the bottom, so you can attach it to any tripod for time-lapse photography, or use the included tripod when you buy the combo package. The packaging contains a basic quick guide, a USB-C cable, a wrist strap and a soft storage bag. We received the combination package for review, which also contains the housing and the tripod. The hard shell case is of good quality and stiff enough to provide good protection. We only wish it was big enough to accommodate the tripod.

The DJI Osmo Mobile 3 combo bundle contains a carrying case and the Osmo Grip

DJI Osmo Mobile 3 performance

Before switching on this device, you have to open it, which is very easy thanks to the spring-loaded arm. Thanks to carefully placed grooves and latches, the arms of the gimbal snap into place when folded so that it does not accidentally unfold. The gimbal must be activated before you can insert your phone into the terminal. To do this, you need to download and log in to the DJI Mimo app, which is available in the Google Play Store and the Apple App Store. As soon as you have gone through the setup process, which also checks and downloads all available firmware updates for the gimbal, you can use Osmo Mobile 3. The gimbal automatically tries to center the installed phone. However, you can also manually adjust the position by holding the tilt motor. You can also calibrate the position and angle of the phone using an option in the Mimo app. The Osmo Mobile 3 is compatible with most of today's popular cell phones, but not all functions are available for all cell phones. For example, slow motion videos and 60fps videos in the Mimo app are currently only available on iPhones. 4K recording is not yet available on some Android phones like the Realme X2 Pro (review), but on others like the Samsung Galaxy Note 9 (review). Even if your phone is not in the list, you can still use all the basic functions of the app. Hopefully we should see better support in future releases. We tested the Osmo Mobile 3 with a variety of mobile phones such as the Redmi Note 8 (test), the Realme X2 Pro Master Edition, the Samsung Galaxy Note 9 and the Apple iPhone 11 Pro. The holder for the phone is also cleverly designed so that it does not come into contact with one of the buttons and you can really center it. We noticed that all of the phones we tested got quite warm after using the Mimo app for a long time and the batteries were quickly discharged as a result. If you are not taking pictures, turn off the screen or put the gimbal into standby to save power for both devices. With Osmo Mobile 3, you can record professional-looking, stabilized videos with little effort. This is particularly useful on phones that don't have electronic stabilization or don't do a good job. With the Redmi Note 8, for example, 4K videos are recorded in good quality without stabilization during the day. The Osmo Mobile 3 fixes this problem and makes an otherwise unusable video clip look like it was recorded with a much more expensive phone. We even tried recording a video while zooming in, which causes blurring even with tiny movements. The gimbal made a big difference even while walking. If you have a high-end phone with optical stabilization, taking photos in low light is still a challenge. A stabilizer for such situations is noticeable in the end result.

The DJI Mimo app offers good functions for recording and controlling the Osmo Mobile 3 In addition to standard photos and videos, the Mimo app also offers other recording modes and functions. You can use it to record professional-looking time-lapse videos in which you can set the path that the gimbal follows for the duration of the time-lapse. Hyperlapse videos are also possible, and we really liked the end results even with a cheap phone like the Redmi Note 8. In story mode, you can easily create short stories. All you have to do is select a template and follow the instructions to record short clips that are then automatically merged with transitions, on-screen text and music. You also have the option of instantly sharing these clips on social platforms. For panoramas, you can choose a 180-degree shot or a wider shot that captures a lot more angles. With the latter, however, the end result didn't always look good, and we occasionally noticed inconsistencies in sewing. In addition, the gimbal of the Osmo Mobile 3 can only be rotated to a limited extent so that you cannot take 360-degree photos or panoramas on it.

A 3x3 panorama that was combined with the Redmi Note 8 by the DJI Mimo app The Osmo Mobile 3 also has ActiveTrack 3.0, which is available via the Mimo app. You can select the object you want to follow through the viewfinder. The gimbal tracks it automatically to make sure it's always in the center of the frame. It worked very well with people, but not so much with fast moving objects. There is a sport mode that can be activated by pressing and holding the shutter button twice. This enables an active tracking of the object in the middle of the frame and increases the speed of the motors so that the gimbal can swivel and tilt faster. ActiveTrack 3.0 can also be activated by showing the camera a palm or a V-sign. However, this must be activated in the settings of the app. Other gestures include double tapping the mode button to rotate the phone horizontally or vertically. and triple-tap the shutter button to switch between the front and rear cameras. You can also activate the quick menu, which allows you to use the joystick to navigate through all shooting modes so that you never have to reach for your phone's screen. DJI specifies a battery life of up to 15 hours. We noticed that the battery life is actually around 10 hours in actual use, which is still not a bad thing. We believe that this should be more than enough runtime for everything you will be filming at the same time. The Osmo Mobile 3 can be used while charging, so you can use it for longer. It took approximately two and a half hours to fully charge when connected to a 10W adapter.

The DJI Osmo Mobile 3 works with almost any phone, but some features of the Mimo app are only available on some models judgment The DJI Osmo 3 is an incredibly entertaining device and a must for any serious content creator. Even for casual users, it is a very practical accessory when you are on vacation or just like to make home videos. The best part is that it is easy to use and even videos recorded with an inexpensive smartphone can look more professional. We love how compact it gets when folded up. The subject tracking function works well for people. and the Mimo app offers useful shooting modes. We hope that DJI updates the app to support more resolutions and frame rates on a wider range of Android phones. The starting price of Rs. 8,999 is very good considering the performance and functions that this device offers. We recommend putting a bit more money in the combo package, as the case is a must if you travel a lot and the tripod is very convenient for time-lapse photography. Price: Case 8,999 (base model); Case 10,999 (combo model) benefits Comfortable and portable Very good stabilization Easy to use Useful companion app Decent battery life disadvantage Object tracking could be better Read the full article

1 note

·

View note

Text

BEST PORTABLE GPS & COMMUNICATORS

Proper navigation is essential, whether deep in the mountains or the open sea. While most current mobile phones include portable GPS capabilities, you’ll want to invest in a separate gadget if you’re serious about navigating.

Unlike phones, Portable Global Positioning Systems (GPS) do not require a cell signal to function. Instead, they connect to the GPS satellite network to determine your location and another network of satellites to transmit and receive communications.

Below, you’ll find some of the market’s best portable GPS & Communicators.

GARMIN GPSMAP 65S MULTI-BAND GPS HANDHELD UNIT

Toss this portable GPS gadget in with your camping kit, and you’ll be set for your journey. It’s robustly constructed with simple controls. It has a sizable, 2.6-inch screen that is not just full-color but also readable in broad sunlight. Unite the ABC sensors and combine them with the satellite signals; the gadget will always know exactly where you are.

KEY FEATURES & SPECS:

Support for GNSS satellites and multi-band technologies

6″ color display with sunlight readability

Integrated navigation sensors

Weather monitoring barometer

Battery life of up to 16 hours

Pre-loaded public-land borders and topographic maps

MicroSD card slot for more data storage

Interfaces with your phone to offer smart notifications

IPX7 water-resistant certification

CHECK OUT PRICING AT BASS PRO

GARMIN FENIX 6X PRO EDITION GPS SMARTWATCH

Garmin has lifted the bar for multisport GPS smartwatches yet again with the Garmin Fenix 6X Pro. The huge display, battery life, and, from an outside standpoint, the comprehensive navigation functions combined with the ability to utilize various topographical maps are outstanding.

Furthermore, multiple training, tracking, and analytical capabilities should warm the heart of any athlete who wants technology to work for his benefit.

KEY FEATURES & SPECS:

Built to military standards

Animated exercises demonstrate good workout form

Uses GPS, Galileo, and GLONASS for navigation

Altimeter, barometer, and 3-axis compass

Long-lasting rechargeable lithium battery (up to 56 days of GPS Tracking in Expedition mode )

51mm waterproof case

Heart rate monitor, blood oxygen monitor, audio player, Bluetooth, Garmin Pay, and more features

Operates seamlessly with both Android and iPhone devices

Impressive range of mapping incorporated inside its 32GB internal storage

InReach capabilities

Solar-powered multisport GPS watch with a 1.4-inch screen

Read More

0 notes

Text

It was Matt’s second day aboard the Castle of Lions when his whole world got tilted on its axis.

He’d taken up Coran’s offer of a change of clothes, putting on a loose but comfortable Altean outfit when he got up rather than his usual heavy Rebel garments. It wouldn’t do to be so casual on a regular basis, as it paid to already be in uniform when the inevitable emergencies arose, but Matt felt like letting himself relax, just for a little while.

The young man had to wander a bit after leaving his newly assigned room, shuffling along the half-remembered route to the kitchen Pidge had shown him the day before. Eventually, he found it, and made a beeline for the food-goo dispenser. It took a quiet cough for him to realize the presence of another, sitting at the countertop.

“Did you have a restful night?” Allura asked, smiling and causing Matt’s heart to stutter.

“Oh, uh, yes! Sort of. I mean, I slept well, after I got off the bed and onto a blanket on the floor.” He chuckled awkwardly, rubbing at the back of his head. “Your mattresses are way softer than anything I’ve gotten used to lately.”

“I see.”

“Uh, what about your night? Get some good rest?”

Allura’s smile got a bit tighter. “As good as I can, in these trying times.”

“Right.” After filling up his bowl and locating a spoon, Matt scooted around to take a seat across from her. Perfectly content to eat in companionable silence, it took him by surprise when Allura’s hand suddenly shot out, seizing his wrist just before he could take a bite of goo.

The princess ignored his startled yelp in favor of staring intently at the purple words printed down his forearm, visible thanks to the short sleeves of his new tunic. “Matt - this soulmark - it’s in Altean script.”

He blinked. Then realization sank in. “But- I thought you and Coran were the only Alteans left...?!”

Allura met his wide-eyed gaze with one of her own. “So I thought. But whoever your soulmate is, Altean is their native tongue.”

Matt had to blink again. “That- um. Huh. Wow.” The shock of that revelation was making it hard for him to formulate a proper response. After taking a few seconds to try and reboot his brain, Matt gave it a second go. “Guess me and Shiro really do have the same luck.”

Instantly, he regretted his words, as Allura released his wrist with a flinch.

“...Indeed,” she said quietly.

Both of them tried to avoid thinking of the Shiro look-alike imposter sitting in a cell in the bowels of the Castle, one with no soulmark to be found upon his skin. They also tried not to recall the multi-hued words the real Shiro bore, once on his right arm and then on his left - Altean words, that translated to What sort of aliens are you people? - or the grey Japanese characters on Allura’s palm that read Confused ones.

They didn’t have much luck.

“...What does it say?” Matt finally asked. “We never could translate Shiro’s, when we were on Earth - what does mine say?”

Allura told him, and he spent the rest of the day hopeful in the knowledge that Pidge would meet and keep his soulmate safe for him.

-V-

Transmission from the Voltron team aside, it didn’t really strike Matt that the Castle was gone until his ship circled the little ball of rock and atmosphere that the five Lion sat on by themselves. As soon as he touched down, Pidge could be seen coming out of Green, running in his direction. Matt met her on the loading ramp with the warmest hug he could muster.

“Shiro’s in Black’s cockpit with Keith and Allura,” his sister told him. “But there’s somebody I want you to meet first, real quick.” Baffled, he let her drag him towards Green, and the slim figure standing just before her. Matt’s attention was quickly caught by the stranger, who had long blonde hair and a tentative smile that made his heart flutter.

“Matt,” Pidge announced when they came to a stop. “This is Romelle. She’s from a secret Altean colony that we’re gonna be liberating once we have a new castleship.” He sucked in a deep breath, hope flaring, before remembering his manners.

“It’s a pleasure to meet you, Miss Romelle,” he said, offering a hand to shake.

Her smile grew bigger. “The pleasure is all mine - your sister has told me so much about you already.”

Warmth exploded along his arm where his soulmark rested, and it was all Matt could do to stare at her in mute shock. Romelle’s eyes, a brilliant shade of purple, were clearly laughing at him. He decided he wanted to see them that joyful every day for the rest of his life.

If I can’t escape the plot bunnies, then neither will all of you.

#voltron#voltron season six spoilers#matt holt#romelle#soulmarks AU#romatt#I'm just not giving matt a poor break#first I ship him with shiro#then shiro and allura#now I'm throwing him at romelle#xD#pidge#allura

38 notes

·

View notes

Text

Website: http://www.forsentek.com/product.html

Forsentek Co., Limited supplys tension compression load cells,miniature load cells,rotary torque sensors,multi axis load cells and related force measuring devices.

miniature load cell

1 note

·

View note

Link

We propose that SARS-CoV-2 gene product, Spike, is able to modify the host exosomal cargo, which gets transported to distant uninfected tissues and organs and can initiate a catastrophic immune cascade within Central Nervous System (CNS). SARS-CoV-2 Spike transfected cells release a significant amount of exosomes loaded with microRNAs such as miR-148a and miR-590. microRNAs gets internalized by human microglia and suppress target gene expression of USP33 (Ubiquitin Specific peptidase 33) and downstream IRF9 levels. Cellular levels of USP33 regulate the turnover time of IRF9 via deubiquitylation. Our results also demonstrate that absorption of modified exosomes effectively regulate the major pro-inflammatory gene expression profile of TNFα, NF-κB and IFN-β. These results uncover a bystander pathway of SARS-CoV-2 mediated CNS damage through hyperactivation of human microglia. Our results also attempt to explain the extra-pulmonary dysfunctions observed in COVID-19 cases when active replication of virus is not supported. Since Spike gene and mRNAs have been extensively picked up for vaccine development; the knowledge of host immune response against spike gene and protein holds a great significance. Our study therefore provides novel and relevant insights regarding the impact of Spike gene on shuttling of host microRNAs via exosomes to trigger the neuroinflammation.

0 notes

Text

Benefits Of Automated Palletizer

Shrink packaging equipment for a broad variety of industries together with pet food, dairy, private care, food/beverage, contract packaging and rolled product. Manually placing packing containers on pallets can be time consuming and costly; it can additionally put unusual stress on staff. The first mechanized palletizer was designed, constructed, and put in in 1948 by an organization previously generally known as Lamson Corp. Warehouses that focus on fulfilling client e-commerce orders are rightly concerned about automation that brings effectivity to the picking and packing of each-level objects for e-commerce fulfillment. But, for many DCs, the process of palletizing stays among the many most labor-intensive tasks check this.

The Science of Palletizing is a 72-page instructional introduction to the basics of unit-load forming and is designed to familiarize you with the fundamentals of palletizing.

A bar code reader registers the product sku's as they come down a conveyor to the accumulation space and the system diverts them into the correct lanes for the robot to pick and place on the pallets. Slip sheets are deftly added between layers because the merchandise are palletized. Once a pallet is fully loaded, it's conveyed out of the palletizing cell for stretch wrapping and further transport. New pallets are picked up by the robotic and put in place, able to receive additional product layers. Columbia manufactures inline high pace, excessive degree, ground stage and robotic hybrid palletizers, load switch stations and offers complete automated palletizer system integration. Macron Dynamics provides a Cartesian fashion MGS-UC2 linear robot equipment that might be integrated into palletizing techniques.

In row-forming palletizing applications hundreds are organized on a row forming area and then moved onto a special area the place layer forming takes place. This course of repeats until a full layer of goods and products are configured to be placed on a pallet. While building pallets manually is a tough job, it can be made simpler without going to a completely automated solution, since semi-automated choices exist. Joe Harris, senior systems engineer with Conveyco, says the company’s semi-automated solution makes use of an ergonomic platform fed by conveyors so that circumstances enter the palletizing station at an ergonomic level for sliding cases onto the construct. Robotic palletizing requires software program person friendliness on a quantity of levels, says Dan Barrera, segment manager with Carter Intralogistics, which provides robotic palletizing. These ranges embrace the software to regulate the robotic arm, software that governs the vision know-how, software program to configure pallet patterns and builds, and software at the WCS/WES degree.

Fully automated palletizing options are particularly enticing for multi-shift operations, explains Harris, since the labor financial savings multiplies more shortly.

The Macron MGS-UC2 gantry product is a robust and sturdy 2-axis system with broad payload capacity.

This palletizer kind utilizes a continuous motion move divider that guides the products into the desired area on the layer forming platform.

We'll be happy to answer any questions you might have, merely click on beneath to get started.

Whether you are palletizing a full layer or particular person bins, baggage, pails or drums our systems are quick, steady, and dependable. The GR-X automated palletizer system is designed to arrange full-height pallets measuring 44”W x 56”L x 110” tall of empty plastic containers or aluminum cans. Unit is configured to handle the vary of container/can sizes and pace of your line. Palletizer operator to be answerable for loading automated palletizer empty pallet, initiating automatic sequence, fastening of pallet banding , placing slip-sheets between layers, and elimination of full pallet. Options to routinely load/remove pallet and routinely place slip-sheet layers can be found.

Columbia’s palletizing solutions are always custom-made to satisfy the distinctive wants of every customer’s application. We have a broad selection of options and features available to ensure your system is optimized in your known purposes today and unknown needs for tomorrow. Columbia's standard high stage palletizer machines set the industry commonplace. Each of these palletizing machines could be upgraded as your business wants change, while adaptable interfaces allow for smooth integration along with your manufacturing equipment. Depending on package deal weight and load configuration, handbook palletizing may be backbreaking work. Automating these processes can cut back publicity to persistent injuries and doubtlessly severe accidents.

We have been providing complete packaging options to all kinds of industries for greater than forty years. The in-line palletizer was developed within the Nineteen Seventies when greater speeds had been wanted for palletizing. This palletizer type utilizes a continuous movement circulate divider that guides the products into the desired area on the layer forming platform. Automated palletizing systems are proven options, and they're changing into extra flexible in accommodating totally different SKUs and duties. Vendors are giving operations loads of alternative, placing more emphasis on software program capabilities and ease of use. Automation frees up costly manpower for extra useful work requiring the human contact, allowing you to utilize labor more successfully in your facility.

An computerized palletizer can decrease worker’s compensation costs and improve worker satisfaction at the identical time. ROBOGUIDE is FANUC’s offline programming product that permits customers to rapidly and easily create, program and simulate a robotic workcell in 3D without the bodily want and expense of a prototype workcell setup. Investing in robotic options, or any capital equipment is a decision no company – massive or small – takes lightly. When our group creates a digital robot workcell simulating your course of using your parts, you presumably can easily visualize your system, see your productivity improve, and minimize risk prior to your buy determination. In addition, palletizing robots may be programmed to handle a quantity of infeeds of different SKUs on the identical line. Vision techniques can be utilized to ship information to the robotic so it could decide and place completely different SKUs on totally different pallets.

Complete Palletizing Solutions

As automated robots do their work tirelessly and carry out consistently, their human counterparts are able to perform different processes and tasks not easily automated. An computerized palletizing system could be programmed for a quantity of stack patterns, with speedy changeover. This flexibility helps to maintain your entire post-production line flowing easily. AMCAP is a high-performance system that builds mixed case pallets and roll containers, permitting retailers to turn out to be value efficient and more aggressive. A robotic solution typically has a smaller footprint and that's a worth when you evaluate the fee per foot in a producing facility. A robotic solution also offers inventive flexibility for set up in tight areas.

These techniques deal with multiple packaging traces with a number of SKUs featuring ALBA pallet dispensers and pallet conveyors that are compatible with many custom-designed case and pallet dealing with techniques. Providers of palletizing solutions usually either have WES/WCS capabilities, or experience in integrating to the WCS layer. Within their palletizing options, some vendors supply tools that enable for visual configuration of pallet patterns. Additionally, with robotic palletizing, some distributors are making use of artificial intelligence , machine studying and vision technology to the software program intelligence for the arms to make them more adaptable.

Innovative Security Know-how

Robotic palletizers had been introduced in the early Nineteen Eighties and have an end of arm device to seize the product from a conveyor or layer table and place it onto a pallet. Both typical and robotic palletizers can obtain product at a excessive elevation, sometimes 7–10.33 ft (2.13–3.15 m), or low "floor level" elevation of 2.5–3.0 ft (0.76–0.ninety one m). The finish of arm tooling has advanced lately to accommodate a variation of pack sample and package deal types. Fully automated palletizing options are particularly enticing for multi-shift operations, explains Harris, because the labor financial savings multiplies more shortly. However, with fully automated solutions, it’s important to know product dimension, weight, and factors like how fragile an item is.

The Arbot is a pre-engineered robotic palletizing cell that mechanically stacks and wraps pallets to precise specs. It can accommodate products up to approximately a hundred pounds, has gripper choices for all types of packaging, and an integrated conveyorized turntable stretch wrapper with a forty five load/hour capacity. Massman Automation integrates ABB, Fanuc, or Motoman robots into the robotic palletizing cell.

That is one reason why some operations use dimensioning and weighing gear near receiving, so package traits are identified by the palletizing answer always. Conventional palletizers take cases fed into the palletizing station from conveyor to construct single SKU and blended SKU pallets. These models can deal with some package variability, however usually aren't as flexible in accommodating completely different sized instances or different packaging as robotic palletizers, which use articulated robot arms.

With a easy design and standard components, PalKombi benefits from a exact mechanical meeting and high-quality components. It affords easy management and entry and is absolutely safeguarded against accidents. Dematic provides a portfolio of user-friendly, cost-effective, high-performance palletising and depalletising systems to handle the complexities of distribution operations. From guide ergonomic palletising & depalletising stations to completely automated robotic options, Dematic modular techniques provide maximum efficiency, flexibility, and reliability. Massman Automation provides a small footprint, low-cost gantry palletizing resolution, a high-entry palletizing answer, and robotic palletizing solutions capable of handling multiple conveyor strains.

Given the current product dimensions, PalletTool will provide a listing of potential pallet patterns to select from giving the space effectivity for every sample. The selected pallet sample as properly as the product weight, the whole number of layers, pallet/infeed retreat, and strategy distances, and gripper data are all saved inside the unit load created. This allows you to simply change between products both at startup or whereas the system is already working simply by altering the present unit load. Conveyco also offers absolutely automated robotic palletizers, as nicely as the software program to devise patterns and assist “aisle-ready” pallets. Being capable of effectively build aisle-ready pallets is important to operations replenishing their own stores or add worth for retail companions, to make the in-store stocking and replenishment extra environment friendly.

Simple and economical, screw pushed actuators are highly modifiable for various functions and perfect for lighter loads and excessive accuracy positioning. Connect with a Dematic representative and we'll help you discover the right resolution for your small business or reply any questions you might have. Dematic works with you to make sure the absolute best performance through the lifecycle of your system. Dematic is optimising your provide chain with technologies which would possibly be remodeling your trade.

To have multiple lines come into a traditional palletizer, accumulation conveyor could also be wanted to buffer the quantities that need to be released and sequenced in front of the palletizers, which adds house requirements and price. With Columbia’s advanced Product Manager graphic-based HMI, our typical palletizers supply unlimited pattern-forming capabilities and zero time — zero software changeover. As an built-in systems solutions provider and residential to the broadest palletizer product line of any standard palletizer provider, Columbia is certain to have a solution for your whole palletizing needs.

“That is becoming a well-liked functionality, to help replenish shops more efficiently,” says Harris. Robotic palletizers can be considered part of the Industry 4.0 trend that brings together sensors and intelligent equipment to create extra adaptable, related techniques for a DC, says Hogg. For example, he says, the tools provides reviews and insights into efficiency, and permits for predictive analytics and upkeep to ensure excessive uptime. “With intelligent gear and the sort of smart facility setups that you just get with robotics, you possibly can really take a holistic take a glance at the whole facility operations,” says Hogg. Most multi-SKU, multi-line standard techniques need significantly extra conveyor than robotic methods, as a outcome of a standard system sometimes only will have one build location, whereas a robotic cell can have multiple build locations.

Top Notch Distributors employed autonomous cell robots to create safer and extra efficient... Using a novel, versatile belt based mostly “rack and pinion” design and structural aluminum MacFRAME elements, our Robotic Transport Units can deal with all kinds of lengths and payloads. Linear actuators supply horizontal and vertical movement with travel as a lot as 500 ft, speeds up to 600 in/sec., and may precisely deal with hundreds up to 10,000 lbs.

“This function is going to reduce your likelihood of product damage and shrink, as a result of you’re not going to be trying to maneuver pallets around that aren’t wrapped, which often is when product damage can occur,” says Harris. Conveyco’s software for palletizing provides visible directions on the pallet construct for the operators, whereas the ergonomic station and platform enable for rapid pallet constructing with out the lifting involved with handbook pallet constructing. Palletizer machines have become a vital a part of automation, replacing human error and damage in manufacturing with effectivity and speed. In addition to such benefits, palletizers can handle environments that would otherwise be injurious to employees. Instead of requiring the rent of extra laborers to do this work, many companies have adopted palletizers into their office environments in order to get the job accomplished extra rapidly, successfully and safely.

In most applications, this can show to be a significant enchancment in efficiency over handbook stacking and manual/semi-automatic banding or stretch wrapping. Our full line of palletizing robots offer you choices in phrases of dimension, payload, speeds for cycle time and precision and most significantly, care in handling your merchandise. From integrating our commonplace robotic palletizers to utterly automating end-of-line packaging methods, we are as a lot as the challenge. Stein explains that Signode can combine with automated palletizers with its own tools corresponding to case packers and stretch wrappers, leveraging APIs and the controls layer to assist an integrated end-of-line solution. Software at the WES degree ensures that several varieties of robotics such as robotic palletizers and AMRs can work in unison.

In its primary model, the empty pallet is manually placed into the machine and the full load is removed with a forklift truck. As an choice, computerized pallet dealing with can be added to the infeed or outfeed of the system. In quick, person friendly software program helps make a system more adaptable to modifications similar to the necessity to add SKUs, says Barrera. “The software for robotic palletizing options should be person friendly, not only to interface with third-party equipment and systems, however to have the ability to dynamically adapt to business modifications,” he says.

Straightforward

Factors like the speed wanted, and flexibility in dealing with totally different package deal sizes and SKUs, are key figuring out components, adds Castor. Columbia's standard inline palletizer machines use a continuous movement move divider that position the product into the accurate position on the layer forming area till a layer is full and placed onto the pallet. A palletizer machine from ARPAC is able to processing 15 to 50 cases a minute and up to forty five palletized loads per hour.

The cell includes a multi-axis robot and dual zone vacuum plate gripper to securely handle one or two cases at a time. It has a nominal fee of 15 cases per minute and a most product weight of 60 kilos and 30 pounds . PalletPRO simulation software can be utilized to completely build, debug and test a palletizing software offline/virtually. PalletPRO allows customers to create a workcell layout, infeed and pallet stations, slip sheet and pallet dispensers. Hundreds of unit load pallet configurations could be created and visualized in 3D using PalletPRO’s built-in library of business normal patterns. The data created in PalletPRO can be downloaded to a FANUC robot controller containing PalletTool® software program.

youtube

0 notes

Text

Multi-Axis Load Cells guaranteed by 20-year technologyl DACELL

DACELL Co., Ltd. is highly specialized supplier for ultra-precision load cells, Compression & tension load cells, and multi-axis load cells based on its proprietary technology accumulated for 20 years of experience.

A load cell is a force transducer. It converts a force such as tension, compression, pressure, or torque into an electrical signal that can be measured and standardized. All load cell products of DACELL are manufactured byits own superior technologies and every effort to provide customers with total solutions for the field of load cells and as well as advanced weighing and measuring field. All DACELL products ensure high quality products with international competitiveness.

DACELL Multi-axis Load Cell MC15has various capacities of detecting up to components with minimized interaction between components.

DACELL Multi-axis Load Cell MC134is a load cell of six-axis that can be order-made on demand in size and capacity for torque and axial force detection. And it is provided with a flange for easy installation. It is most suitable for use in materials testing machines.

DACELL Compression &Tension PS151 and PS131 load cellscan be used for Crane and Overload applications. Both are Nickel plated for corrosion resistance.

DACELL Compression &Tension UL18A-T1 and CP66 load cells are compact and low-cost, shear-type compression load cells. Both are comparatively low-cost shear type transducers with a high accuracy of 0.02% R.O. And both ranked protection class IP65.

DACELL Compression &Tension load cells CMT can measure electrode force, one of three major factors on welding, accurately and easily.

DACELL Compression &Tension CB1, CB1A load cellsare strain gage load cellsnewly developed as an electronic "Scale" for commercial purpose with the characteristics of high accuracy and low price. Both provide small displacement to be compared with other mechanical means. Due to electronic output, both are easy to treat various treatments.

DACELL Compression &Tension CB41 is a single-point load cell and has high accuracy and low price. It is suitable for low-profile scales and automatic check-weight systems.

DACELL Compression &Tension CBC is equipped with stainless steel bellows seal. It can be used for both compression and tension measuring and compact, lightweight, and easy-to-mount.

Click here to contact DACELL.

View more:Dacell Multi-Axis Load Cells

0 notes

Text

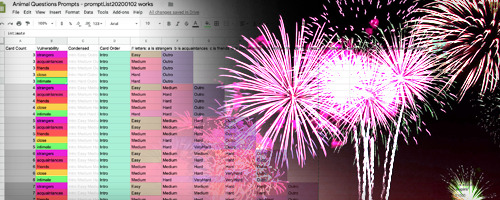

New Year’s New Functionality!

The holiday break is over! It was used to fundamentally redefine some major aspects of gameplay. That includes: 1) new vulnerability settings, 2) new questions-per-session settings, 3) automatic online updates for those new questions and card orders, and 4) almost 200% more questions to draw from for gameplay! Requests for more customization ultimately led to a ton of new functionality, and even cloud downloads on the backend. So a lot happened for a workweek that was technically only two days in the office! And it was largely a pretty productive holiday week!

Color coding for vulnerability in our new questions spreadsheets!

New Vulnerability Settings

Close and Intimate settings, or regular friend settings in longer sessions, can now get the occasional “Very Hard” question or two. These are pretty intense! They are for an audience that kept asking for more or deeper questions when playing with closer friends though, and that asked for far fewer or less intense questions when playing with strangers. “Easy” is also reimplemented as a category for that reason. Offline CSV file loading was added so we could more easily do detailed passes, spreadsheet formatting, and more to deal with how many categories we now had and the increasing the number of questions. What was recently 67 questions has now been expanded to more than 200 - now allowing for a much wider range of playthroughs that facilitate longer, shorter, harder, and easier sessions - and even ones where no categories are marked off by players at all! (We have a few generic, safe questions in there just in case)

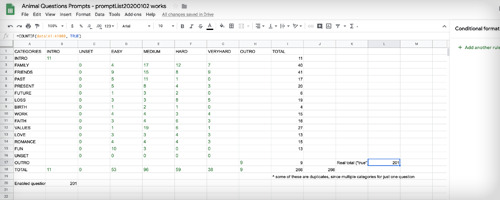

Grid arrangements to keep track of exact counts for every category/difficulty!

New Difficulty Escalations

Adding more questions meant redefining the card order too - now we have templates for “what difficulty of card should go when” depending on multiple factors. The grid’s two axis were “how many questions were requested (between 3 and 7)” and “what level of vulnerability was chosen” and then each of those cells has a template list for what difficulty of question to use when. Now for example: an especially vulnerable and long session can ramp into very hard questions and stay there, or by contrast, a long session among strangers can stay pretty light the whole time (and maybe get a little deep eventually). Close friends in a quick session might also get deep, but strangers can try the game briefly without getting deep at all. Being online lets us fine tune these over time too. Giving the player those options for vulnerability (stranger/acquaintance/friend/close friend/intimate friend) and session length (3 questions, 4 questions... up through 7) gives us a lot more room for making the game even stronger for any audience.

Each bar is a category (faith, love, loss), color is vulnerability, height is quantity.

New Question Spreadsheets

These new spreadsheets are powerhouses. They keep track of every category of question, their vulnerability level, and how many of each we have in every one of those settings too. The goal was to quickly iterate on the data, but the data visualization allows us to instantly assess what categories are lacking even in complex overlaps with multi category data too. That means if each question has three labels (eg. family friends and loss) we can measure it as contributing to each of those categories having a question at that vulnerability level. The graph above is an example of looking at all the data at once, and seeing the colors represent which categories need fleshing out in which vulnerability levels. So even though the goal was just to make fast text changes, the visualization power is letting us make a much more well balanced and refined game. What we weren’t expecting though was the near seamless online integration, and how easy it was to get hooked into Unity.

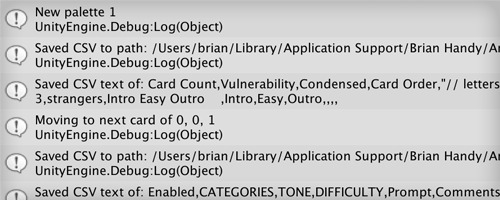

Pulling tiny amounts of data to avoid heavier app updates!

New Online Updates

Those Google Sheets files work surprisingly well being pulled straight into Unity. We publish them as CSVs online, so while not totally invisible to the user, they are instantly and easily accessible from the code. With HTTPS security too, we’re not too worried about code injection or security risks on this front either. Both question information and difficulty escalation information are now updated on every new session, and the latest files are stored on device. Any new copy of the game from this point forwards will always have the latest data for not a lot of download. It’s only 23kb total right now, which is one thousandth of a percentage of the average 3GB monthly data plan. That’s pretty cool for instant, free, and trivially easy online updates forever!

This website is old, but the people behind it are young and full of life!

Old City Tax

There was one thing that wasn’t a productive code spreadsheet this past week. Bureaucracy can be tricky, and it’s sure not fun being the 830th caller in line (I wish that was an exaggeration) or waiting days for a return call to make sure you didn’t miss a major deadline. But once Los Angeles is on the phone with you, they are actually pretty good at the business and government stuff, even for folks who aren’t familiar with it! New businesses open all the time in this city, and if you do a little of your own research too, you might luck out with as pleasant an interaction with the department as I did. I recommend reaching out to them and taking advantage of their opportunities to help new businesses get their paperwork in order - even if it takes a few days and multiple hundreds of callers to get called back. I just wish I had called a little sooner!

Thanks, LA City Finance!

Conclusion

I spent the first half of this week making a totally unrelated “Matrix inspired” robo caller game, working with a voice actor, writing a script, sending lots of messages, and creating something in a tech I’d never used before just for an experiment for a cyber punk themed new years party. It was tons of fun (a silly idea gone out of control), and I didn’t get to use any of my normal programming skillsets. That’s what most of working on this conversation starter guessing game has felt like over the last four months. Totally new, thrilling, and no ties to anything I know or am comfortable in. But every now and then there’s a week like this where I just get to sink into code and libraries and web and gameplay. And it’s still always wonderful. I feel incredibly productive after all that, and I’m looking forward next week to getting back into things like funding, marketing, and publishing where I have again it’s all new work to me. It’s exciting stuff, and I feel lucky to be doing every side of this job.

1/3/20

0 notes

Text

Fasting!!

If you follow diet and health trends you have no doubt heard of Intermittent Fasting. What was once rejected is now becoming and more and more accepted, and with good reason. In reality, Intermittent Fasting is nothing new. Various forms of fasting have been practiced for thousands of years by various cultures and religions.

Intermittent fasting is not a diet and it does not mean starving yourself. It simply means that everyday you have a fasting window, and an eating window. Fasting for 16 hours a day with an 8 hour eating window is probably the most common version of Intermittent Fasting.

Why should you practice I.F. and possibly even more prolonged, periodic fasts? Put simply - it is a way for our bodies to rest, reset and heal. Constantly digesting and breaking down food (such as with common recommendations of 5-6 small meals a day) uses up a lot of our bodies energy. When we give our digestive system a break from all the constant digestion, our bodies can go to work on healing and repairing itself. Yes - it is also great for breaking down and burning body fat!

Intermittent Fasting is as simple as skipping/pushing back that first meal of the day, and extending the "fast" we all experience while we sleep. When we wake in the morning, our bodies are in the perfect fat burning state. Insulin levels are low - and cortisol should be at its peak for the day. This is a great scenario for fat burning. However, if you consume breakfast insulin levels will shoot up and this process is halted.

I.F. has been shown to increase insulin sensitivity, increase HGH levels, and naturally increase testosterone in men. This is all indicative of a "youthful" hormonal environment in the body that is associated with burning fat and preserving/building muscle and that lean, sexy physique everyone is looking for! Many diets focus on greatly reducing specific macro nutrients and food groups for specific, perceived health benefits. However, a simple daily fast will probably yield you around 90% of the benefits of MULTIPLE, more restrictive and complicated diets.

Many choose to adopt a low carbohydrate diet to hopefully lower and optimize insulin levels. Carbohydrates are not the only foods that trigger an insulin response however, many protein sources do as well. In fact; beef (a ZERO carbohydrate containing food) has been shown to raise insulin levels higher than many high glycemic index foods. Nothing will lower and optimize your insulin levels faster that fasting.

Other diets call for lower amounts of protein as a way to increase longevity via a mechanism called autophagy (more below). These same benefits can be achieved by a short daily fast. Lastly, low fat diets are still commonly used as a way to drop excess body weight. While fat does not inherently make you fat; fat is the most calorically dense macro nutrient - yielding 9 calories per gram while protein and carbohydrates both contain 4 calories per gram. This last point is important because while fasting can help naturally optimize hormones and place you in a more ideal scenario for fat burning - the #1, most important factor with weight loss is still calories in vs. calories out. When you have a smaller time frame to consume all of your daily calories (lets say an 8 hour eating window vs the more common 14-16 hour eating window) you are going to find it much harder to over eat.

How does increased longevity and lifespan sound?

Thanks to a process called autophagy, an increased longevity and lifespan is yours - for free! Autophagy is a process where your body removes toxins, and repairs and recycles damaged cells throughout the body. When our body is loaded with damaged and under performing cells we can feel tired, sluggish, and depressed. Damaged cells can also turn into free radicals causing additional health issues.

The powerful process of autophagy is put into a higher gear after only 14-16 hours of fasting! More prolonged multi day fasts increase it even more - up about 330%! Multiple day fasts are a powerful tool for your health that can be utilized periodically to achieve greater levels of autophagy and detoxification, but shouldn't be utilized all the time as they will no doubt register as a stress on the body. Doing a 24-48 hour fast 2-4 times a year and practicing I.F. the rest of the time is a great combo for you to optimize your hormones, support weight loss and obtain the many detox and life extension benefits without all the stress that typically comes with longer fasts.

Fasting is also associated with improved blood markers such as: lowered cholesterol and triglycerides, lowered blood sugar, lowered inflammation levels along with improved gut health and digestion, better focus and cognitive function, better sleep and on and on the benefits go.

Enough of the why...let's talk about how we should implement all this!

This is all as simple as skipping breakfast and abstaining from food and calorie containing beverages until you ready to break your fast. Know that there may be an adjustment period for you, especially if you've been consuming breakfast and or consuming several small meals a day for years like most people have. Give yourself a couple weeks to adjust - and if there is a day where you need to eat breakfast or an earlier meal, it's okay! Listen to your body and keep working up to daily 14-16 hour fasts. Before you know it your body will have adjusted and you'll be fasting with ease. At this point you will also notice more stable energy levels, better focus and less brain fog.

Before adopting Intermittent Fasting about 5 years ago, we always had to consume breakfast, had to eat every few hours and if we didn't, look out! We experienced blood sugar fluctuations, brain fog, mood swings and quickly became "hangry". There was of course an adjustment period as we adopted to I.F. We can now fast for 16, 18 even 20 hours with ease! We have done several multi day fasts now, and we must say, there is something very powerful and liberating knowing that you are in more control of your body, and don't always have to worry about when then next meal is coming, and or needing to bring bars, shakes and containers of food everywhere you go.

During the fast you can and should stay hydrated with all the water you need as well as other zero calorie drinks such as tea and black coffee. NO sugar or cream in your coffee as these items contain calories and will break your fast! Black coffee is actually a powerful tool to utilize with fasting. It has also been shown to increase autophagy, contains antioxidants and is a powerful appetite suppressant. Just don't over do it; everything in moderation.

Other tools we like to utilize during our fasting period is adding just a couple drops of various citrus essential oils from Young Living's Vitality line to our water. These essential oils are zero calorie, support our bodies detoxification process, metabolism, taste delicious and contain many antioxidants such as D-limonene.

Read more about D-limonene here: https://yldist.com/willrachevans/d-limonene To be clear, we are ONLY talking about ingesting Young Living's essential oils, NOT the oils off the store shelf which can be up to 95% filler, alcohol, vegetable oil and other junk. Did you know that it takes 75 lemons to make just one 15 ml bottle of Young Living's lemon essential oil? And that's just from the rinds! Truly powerful stuff!

Vitamin, mineral and herbal supplements are also fine to take during your fast as they do not contain calories.

Again, give your body a little bit of time to adjust, stay hydrated and stay consistent. You will be blown away by the results!

Thank you for reading and best of luck!

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC329619/?page=6 https://www.ncbi.nlm.nih.gov/pubmed/20534972 https://www.ncbi.nlm.nih.gov/pubmed/17372321 https://www.ncbi.nlm.nih.gov/pubmed/?term=Pituitary-testicular+axis+in+obese+men+during+short-term+fasting.

0 notes